The ceremony took place at the Aksaz Naval Base in the presence of the Turkish Minister of Industry and Technology, the head of TUBITAK, the manager of TUBITAK SAGE and representatives of the Turkish Navy.

During the ceremony, the DATA test-bed was submerged to a depth of 14 meters with the help of a crane. The test capsule inside the system was fired after a countdown by the Turkish minister, and the test firing was successfully carried out. The capsule came to the surface seconds after the launch.

“This system is an infrastructure where all submarine weapons can be tested, as well as all missile systems fired from the submarine to the air, land, and surface, without the need for a submarine. Clearly, such a capability will accelerate the development of critical weaponry, particularly guided missiles for submarine usage.”

Mustafa Varank, Turkish Minister of Industry and Technology

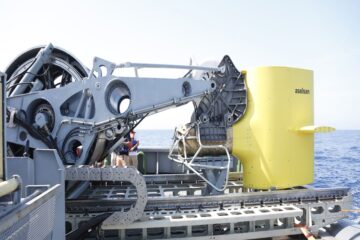

DATA, which allows submarine weapons testing without the use of a submarine, was developed in the same way as the Gür and Preveze class (Type 209/1400) submarines’ launch systems. The system can fire underwater weapons to depths of 60 meters and can also be controlled from shore. DATA’s various sensors provide a safe and controlled test environment, while firing is quick and cost-effective.

The system has standard 21-inch (533 mm) launch tubes and ensures that test firings are conducted under the same conditions as submarines, but in a safer, faster, and less expensive manner. DATA will likely be used to test the submarine-launched variant of the new ATMACA anti-ship missile.

Gurcan Okumus, the manager of TUBITAK SAGE, stated that the system took a long time to develop. He underlined the contribution of the domestic companies in the development phase, saying;

“Both the mechanical, electromechanical and control systems were completed as part of our system planning and project execution with the cooperation of our domestic engineering companies.”

Gurcan Okumus, Manager of TUBITAK SAGE

KATMANSIS & DATA to improve the Turkish Navy’s underwater test capabilities

KATMANSIS

Turkiye’s Istanbul Technical University (ITU) Faculty of Naval Architecture and Ocean Sciences inaugurated the first “Large Cavitation Tunnel and Maneuvering Experiment System” (KATMANSIS) on December 17, 2022.

According to official data, KATMANSIS is the seventh-largest cavitation tunnel in the world in terms of both size and flow rate. In addition to improving the hydroacoustic properties of the Turkish warships, it will be used for a variety of purposes, including propulsion of ships and submarines in both fast and quiet modes, navigation in terms of performance and low noise, and special design of propellers to reduce cavitation.

In particular, this system will help to power warships and submarines with low noise levels, which is important for performance in both fast and quiet sailing, as well as the integration of sonar dome and hull, shape optimization to ensure uniformity of axial velocity on the propeller disc, and special propellers to reduce cavitation.

In addition to warships and submarines, the cavitation tunnel is also used to study the flow characteristics, noise signature, and drag of torpedoes, autonomous underwater vehicles, missiles launched from submarines, and the like.

Why such test systems matter?

The test-beds such as KATMANSIS and DATA are very beneficial in increasing the number of tests and the type of tests. This is because there are some requirements and procedures to test live underwater weapons such as missiles and torpedoes. The Navy must provide a submarine, publish a NAVTEX/NOTAM to warn seamen and airmen of dangerous activity, and provide patrol boats for area security.

Such tests affect freedom of navigation and are very costly as they involve at least 4 to 5 ships and consume fuel (submarine, target tug, patrol boats, etc.) In addition, the test can only be conducted once with the units involved. For live missile tests, this process is even more difficult, as the launch range increases enormously due to the range of the missiles.

DATA and KATMANSIS will make it possible to test systems and weapons before they are deployed, more so than in the traditional way. They will support the research and development phases by simplifying the testing procedures and making them cost-effective. The more weapons are tested, the more reliable they will be.