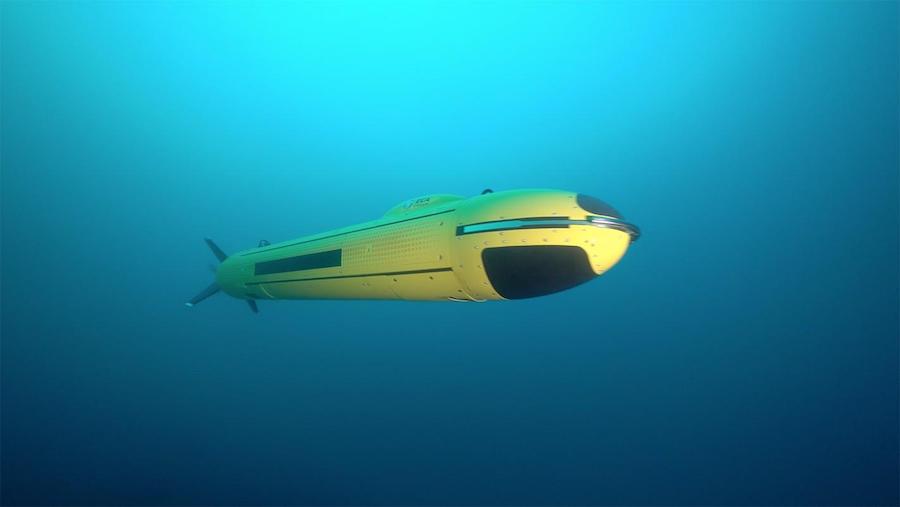

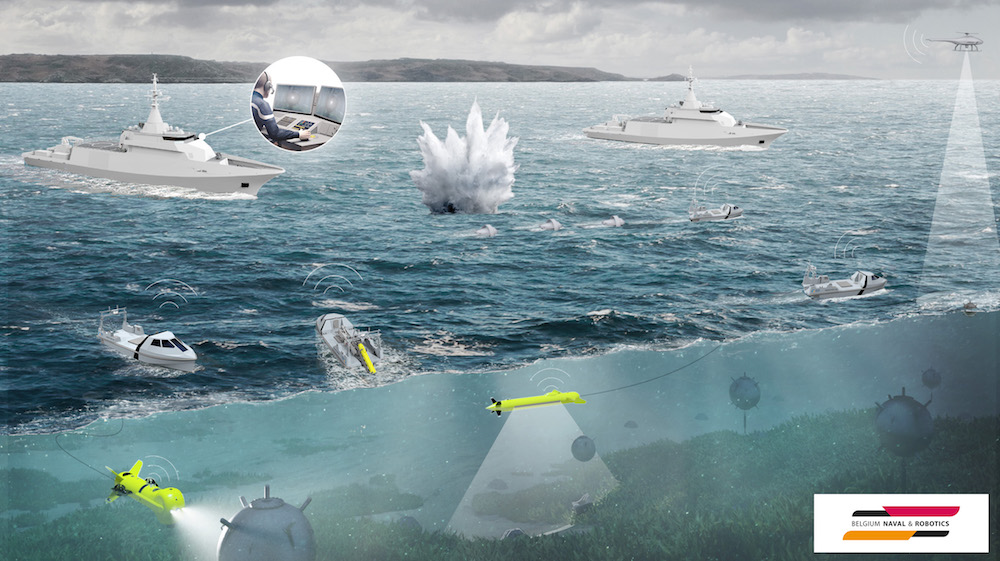

Signed as part of the MMCM Program being led by the Belgian MoD, this contrat will see ECA deliver 10 « Toolboxes » composed of an array of autonomous systems. Each Toolbox will be able to integrate the Inspector 125 unmanned surface vessel (USV), the A-18M autonomous unmanned vehicle (AUV), the T-18M towed sonar, the SEASCAN remotly operated vehicle (ROV), the K-STER mine disposal system, a sweeping system developed by Poland’s CTM, and finally, the 200 kg-class VTOL unmanned aerial vehicle (UAV), most probably the UMS Skeldar V-200. These systems will all be fully integrated to ECA’s MCM UMISOFT C2 system, which will be connected with Naval Group’s SMMD system to form a new mine warfare mission system integrated into the mother ship’s combat system.

Naval News sat down with ECA Group’s Daniel Scourzic, VP Strategic Programs, to learn all about the company’s wide offer.

Naval News – Which elements of the offer made the difference compared to your two competitors ?

Daniel Scourzic – The MMCM program is based on the acquisition of recently developed unmanned systems which performances have been successfully demonstrated in the North Sea in 2016 and 2017. Of all the drones provided by ECA Group, only one was around back in 2014. The rest of them have been developed during the past five years.

In addition, the rapid progress of robotics technology allows the Belgian-Dutch Toolbox to benefit from the latest advances in term of size reduction, weight, autonomy, payload consumption, battery, etc. while maintaining equal or superior performances compared to the drones being developed for the FR/UK MMCM program.

Reducing drones’ weight, for example, makes it possible to board them on small USV vessels equipped with fully automatic launching and recovery systems (LARS). This concept has been successfully demonstrated through the French Armed Forces’ « Espadon » (Swordfish) concept study. It was not retained for the FR/UK MMCM program because of the size that the USV would have to be to carry the A-27 AUV chosen at the time by the French part.

The Inspector 125 surface vessel, based on a Mauric design, was therefore designed to facilitate the deployment and recovery of surface and underwater drones even in high sea states (up to level 4). To this end, the Inspector 125 is fitted with a system that reduces vessel’s rolling up to 40%. In addition, the platform is completely unsinkable, being derived from a series of 20 ships built for the « Société Nationale de Sauvetage en Mer » (SNSM), which i.a. gives it a better resistance to underwater explosions.

ECA’s Inspector 125 is also equipped with a 3D sonar offering unmatched detection and classification capabilities. The sonar, for example, detects nets and obstacles arranged by the enemy around the mine to deceive the AUV.

The Toolbox that will be produced for the MCM program was designed to reduce the logistic footprint and the ownership costs. Being the sole designer and possessing the intellectual property of underwater and surfaces robots enabled ECA to maximize the use of common components and subassemblies. This has a significant impact on the mothership, that will host and implement them, and particularly regarding the hangar size, therefore the size of the ship. Common components also mean common spare parts, as well as easier training and maintenance for the sailors.

Just to give you a concrete example, the T-18M towed sonar is directly derived from the A-18M AUV. The two systems share 80% of common elements. In addition, since the T-18M is fitted by batteries, it is no longer necessary to power it through the towing cable, which makes it possible to use a small diameter cable and consequently lighter towing winch and electric generator on board the Inspector 125. The LARS aboard the USV is also common for the A18-M and the T18-M unmanned systems, only the interface with the front part of the USV needs to be switched. All this leads to reduce stored material and spare parts.

All drones are integrated into the UMISOFT MCM command and control (C2) system, which is connected with Naval Group’s SMMD system to form the mine warfare mission system integrated into the ship’s combat system. This is a great advantage in terms of operations and cybersecurity.

The whole is managed by a single mission system (Integrated Mission Management System (IMMS)) based on two systems: Naval Group’s C3 I4Drone and the ECA Group’s UMISOFT C2 system, which are fully integrated and provide supervision, mission planning / preparation, real-time mission management and data analysis from all drone sensors. IMMS can be implemented from the sea or land.

Naval News – Does the constitution of this toolbox include a part of development to match the specific needs of the Belgian and Dutch Marines?

Daniel Scourzic – The needs of the Belgian and Dutch navies require us to adapt some of the drones and systems including the USV. Minor tweaks on other robot systems are necessary as well, in order to integrate features requested by the customer. In addition, UMISOFT will be adapted in order to integrate the mine sweeping system and the UAV. The sweeping system could be provided by Poland’s CTM and the UAV by UMS Skeldar.

All the planned R & D activities are articulated in a coherent way with the program: We propose first an innovation approach, both in terms of technology (AI, simulation, technological experimentation at sea, cyber security) and in terms of local partnership (academic cooperation, accompagnement of the Belgian Navy with their evolving needs and the ever changing operational threat). This approach captures all that technology can bring to improve the performance of mine warfare systems but also takes into account the feedback of operational users.

This continuous innovation process benefits firstly the development of the MCM program itself in a de-risking process: sharing of the simulation environment to perform onshore systems tests, qualification work on the delivered version allowing to capture in passing the point of view of the Belgian sailors on what is delivered and thus to anticipate the demands for future evolutions), presence on site of the project management team in contact with all these works so more able to take into account mature technological developments and new employment concepts.

But the process also benefits the future versions of the MCM program and in particular those of its toolbox: it feeds concretely the process of evolution ensuring a close proximity between those who think about the future, those who experiment new functions and technologies and those who will implement them operationally: Thus we will be able to define in a concerted and progressive way the capacity increments of future versions of the NMCM program in a logic of “Rolling Toolbox ». The Belgian-Dutch program also includes a whole program and setting up structures dedicated to R & D.

In addition, the Belgian Navy has already planned to upgrade the Toolbox after commissioning, particularly in the framework of the European PESCO MAS MCM program, to which ECA Group is obviously associated, but also in the context of other R & D programs.

Naval News – Which partnerships are established in Belgium and specifically focused on this toolbox?

Daniel Scourzic – An industrial cooperation and know-how transfer plan over the next 20 years:

– more than 39 partnerships in all Belgian regions.

– Sustainable economic spinoffs:

• over 350 jobs per year (full time equivalent) with very high added value created over 20 years

• A positive impact in all regions 35% in Wallonia, 15% in Brussels and 50% in Flanders

This will involve, from the design phase, a wide range of Belgian suppliers and partners in order to develop and sustain the Belgian defence industry. 39 partnerships have already been signed. Six others are in the process of being finalized, bringing to 45 the number of partnerships signed with key Belgian players. The different partners will contribute to three types of activities: construction & integration, re-research & development (R & D) and maintenance (ISS).

– Innovative SMEs: eg DotOcean, BATS and Space Applications for Robotics and Artificial Intelligence, Nviso for Cyber Security

– Major manufacturers: eg ABC on the dynamic vibration damping of the engine, CMI defense, for a digital simulation environment shared between R & D and training and Akka Belgium for integration on board.

– Universities ex: two Brussels (ULB and VUB) and the University of Liège on very innovative technologies to optimize the management of energy or tele-operate swarms of drones for example,

– Research centers, eg VLIZ and the RBINS to experiment with new technological solutions at sea, especially with the future vessel Belgica.

– Belgian engineering associations, IE.net and FABI to facilitate the recruitment of Belgian engineers to rig the two Belgian entities of Naval Group and ECA Robotics

– The association of Belgian shipowners, RBSA, for the application to civil maritime domain of the activities of the Cyber Lab or the MCM Lab.

Our partners are key players in the Belgian defense industrial and technological base, from an industrial point of view but also in the field of R & D. Several of them were already partners of one or both companies via other programs, while others are new partners with whom extended agreements with other prospects are envisaged.

Naval News – Is ECA in charge of training future crews? Will this component rely on the simulation tools proposed by John Cockerill (ex-CMI Group)?

Daniel Scourzic –Belgian and Dutch crews will be trained in the months preceding the delivery of each vessel. These training sessions will start on the simulator delivered to the EGUERMIN training school (Ostend) and will then continue onboard the ships. For the Toolbox, ECA will train navy trainers in the use and maintenance of shipboard robots (OLM) and train navy maintenance teams for onshore maintenance (ILM, DLM).

An awareness of the use of drones could start long before existing systems, but the realization of training too early is of little interest because the trained people may forget everything if they can not quickly implement the knowledge acquired . The simulator is Naval Group’s responsibility and therefore the choice of partners for its development and its realization as well. ECA can not comment on this subject for Naval Group, but CMI Defence [Now John Cockerill] is in the list of identified partners. We will contribute by providing all the necessary bricks and digital models.

Naval News – What is the planned schedule for ECA? When should the construction of the planned Belgian production unit in Flanders begin and when should the first toolbox of assembly lines be released?

Daniel Scourzic – This contract is an opportunity for ECA Group to settle in Belgium. A company, ECA ROBOTICS BELGIUM was created in November 2018 with headquarters in Brussels.

ECA ROBOTICS BELGIUM will have two locations in Belgium. The first one, located in Brussels, is in charge of program management as well as studies and developments relating to drone systems. The second one will be mainly a production unit. Located in Zeebrugge, this plant will be responsible for the production and maintenance of Toolbox subsets. For this purpose, it will coordinate relations with the Belgian suppliers and partners identified for the implementation of the program. This plant is expected to open in the second half of 2020 in accordance with the program schedule. This site will also be in charge of the qualifications and sea trials consecutive to the updates of the drones and the system as well for the program as for the export. The R&D structure of ECA ROBOTICS BELGIUM will carry out, starting this year all the adaptations of drones and systems necessary for the program, in conjunction with ECA ROBOTICS. Specifically on two elements of the drone system: the USV ( surface drone) and the UMISOFT MCM C2 software suite.

The first ship + drone set will be delivered in 2024. The unmanned systems that make up the toolbox will obviously come out several months before to do all the system tests before integration on the first ship. The next set will be 12 months later, then every 6 months for the following.

Naval News – Will Belgium Naval & Robotics be the preferred intermediary by ECA for the export marketing of this toolbox? What are your prospects for exporting in the coming years?

Daniel Scourzic – The consortium is planning to export from the Mine Warfare Business Units created in Belgium to new French and international customers who would show interest in this capacity and in the know-how of Naval Group and Eca Robotics (ECA Group).

Several major navies including France, India or England will renew their mine counter measure fleets in the coming years. In addition, ECA Group believes that most navies will also be equipped with procure transportable drone systems that can be used from the coast as well.

Finally, the R & D actions work resulting from the programs are also a strong commercial argument strength. The innovations and the acquired know-how, under the control of the Belgian authorities, will also be able to nourish the capacity help to win export offers: with this unique and innovative experience but also the “sea proven” character stamp of the solution Belgian, Dutch and French partners in these R & D work actions will be remarkably well placed to convince the many prospects likely to acquire mine warfare systems in the next 20 years.

Naval News – Does the ECA Group offer chosen by Belgium and the Netherlands correspond to the needs of France and its SLAMF program? In this context, what can ECA Group propose?

Daniel Scourzic – As a drone system maker, with our 50 years of experience in the field of mine warfare and with the recent success in Belgium, ECA Group hopes to play a bigger role in the SLAMF program. Together with our partner Naval Group, we have won the trust of the Belgian and Dutch navies. For France, we are willing to offer unmanned systems adapted to the operational needs of the French Navy and derived from the Belgian solution in the best configuration of industrial and commercial partnership. Our solution is sufficiently complete and flexible to be able to be adapted to the specifications of the French Navy, and if necessary to integrate other systems coming from third manufacturers.